The new ejector-pin labeling functionality was specifically created for plastic mold designers. It allows you to identify all ejectors in a mold design project and also create an ejector table. You can also create constraints that simulate the effects of a uniformly distributed blank-holder force. You can define a friction and force value for the blanking phase. This allows for a more precise blanking process that provides additional support during the design phase.

Vero Visi 2019

Password 123

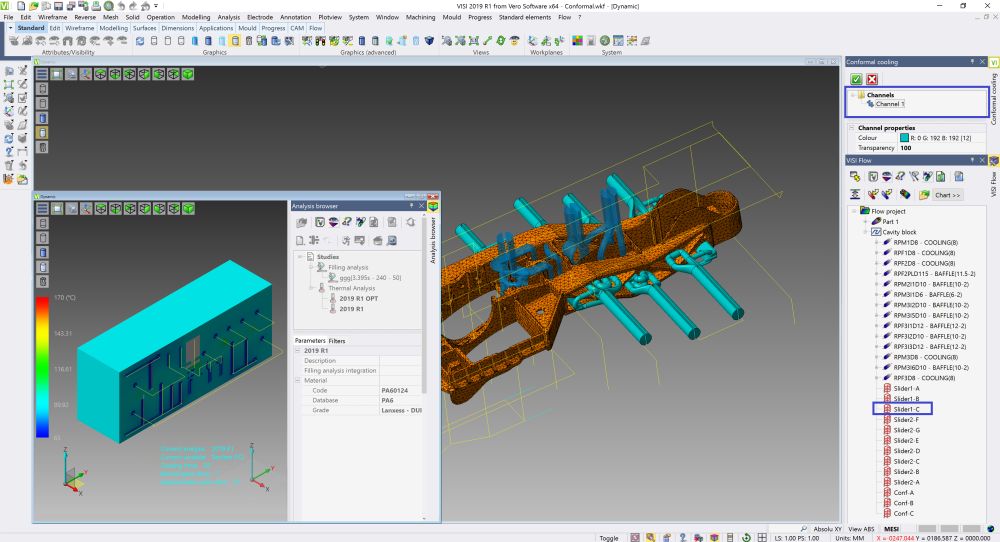

The 2019 R1 VISI software release includes a boost in reverse engineering and a range of new and improved CAD/CAM functions to serve the mold-and-die market. The 2019 R1 VISI software release includes a boost in reverse engineering and a variety of new and improved CAD/CAM functions to the mold and dies market. The new ejector pin marking functionality has been developed for plastic mold designers.

Vero Visi 2019 Feauters

It comes with a variety of tools that can be used to survey and prepare model geometry. The new ejector pin labeling function has been added to the machine.

This allows all ejector pins within the mold design project can be identified in the table using a user-definable label. It allows for advanced sketching and the use of wireframes. The new conformal cooling channel functionality provides advanced sketching capabilities to assist the designer during this phase of the design process. You can use a conformal wireframe circuit that has been previously created. Select predefined or user sections and the conformal channels will be automatically created to form the desired conformal cool circuit.

The new ejector-pin labeling functionality was created specifically for plastic mold designers. It allows all ejectors pins in a mold design project to be identified in an Excel table using a label that can be customized by the user. This simplifies the process of maintaining the mold, especially if one or more ejectors’ pins have to be replaced. VISI 2019R1 provides a direct interface to several portable Hexagon scanning devices, both Romer and Leica.

It also offers an enhanced dedicated module that produces a high-quality mesh that is ready for manufacturing. To facilitate model comparison, gap analysis, and optimized toolpaths, scan data, stock, or reference casting mesh models can be easily aligned with the original geometrical card model. VISI Flow’s Thermal Analysis automatically manages all the information about the conformal cooling that was used during the design phase. The Flow thermal analysis has been improved to display a graphic temperature display on a section of the inserts. This simplified mold design and flow analysis process is now much more efficient and saves time.

You can also edit these channels after subtracting from the mold insert. This new functionality for ejector-pin labeling, designed specifically for plastic mold designers allows all ejectors pins in a project to be identified in an Excel table with a label that can be customized by the user. This simplifies the mold maintenance process, where one or more of the ejector’s pins must be replaced. It quickly identifies and updates any ejector pin needed for maintenance, and if necessary, it will replace it. You can also edit these channels after subtracting from the mold insert.

How to Get Vero Visi 2019 for Free

This package includes specialized tools for optimizing, managing, and generating CNC machining toolpaths in a variety of industries and material applications. Here are some of the notable features that Vero VISI 2019 will offer you.

This results in a simplified mold design and flows analysis process that is both time-saving and efficient. The enhanced blanking process allows you to place faces on models that are affected by the pressure pad. This is done by specifying the relative force to be applied. You can also set constraints to simulate the effects of a uniformly distributed blank-holder force. This results in a more precise blanking process that supports the designer during the design phase. VISI 2019R1 now offers advanced sketching for conformal cooling channels. This function allows you to use wireframe circuits that were previously created in CAD. You can also select predefined or user sections and it automatically creates conformal channels to form your desired cooling circuit.

It can be used in conjunction with the enhanced dedicated module to provide a reverse engineering solution as well as the ability to generate casting and stock models using VISI’s existing modeling and machining environment. All ejector pins within the mold design project can be identified in the table using a user-defined label. The reverse module has been enhanced to provide new functionality to assist the designer in the points cloud to surface model generation. It extracts key geometrical references from the refined mesh and provides additional support for the designer. It allows for the use of wireframe circuits and the ability to perform advanced sketching of the conformal cooling channel. Vero VISI 2019 offers a variety of CNC simulation applications, factory automation solutions, and computer-aided manufacturing programs for different production methods. This application is impressive and offers many different CNC simulation applications, as well as factory automation solutions and computer-aided manufacturing packages.

This results in a simplified and faster process for mold design and flows analysis. This allows for a points cloud to be loaded directly or indirectly. The relative mesh can also be created by using different options for refinement and smoothing. You can create surfaces automatically or semi-automatically using different key geometrical references from the refined mesh.

The VISI Flow thermal analyses project automatically manages all information regarding conformal cooling in the design phase. The Flow thermal analysis also provides a visual display of temperatures for a section dynamic on the inserts.

Scan data, reference casting mesh models, and stock data can be easily aligned to original geometrical CAD models using dedicated commands that allow for comparisons, gap analysis, and optimized toolpath processes. To set the faces of the model that are affected by the pressure pad, the blanking process has been improved. Simply define the relative force to be applied. VISI 2019 R1 is part of a larger project to reverse engineer and cast. It provides an extended interface to several portable measuring arms and Leica scanning tools from Hexagon.

Vero Visi 2019 System Requirements

- Operating System: Windows 7/8/8.1/10

- Memory (RAM): 4 GB of RAM required.

- Hard Disk Space: 3.5 GB of free space required.

- Processor: Intel Dual Core processor or later.