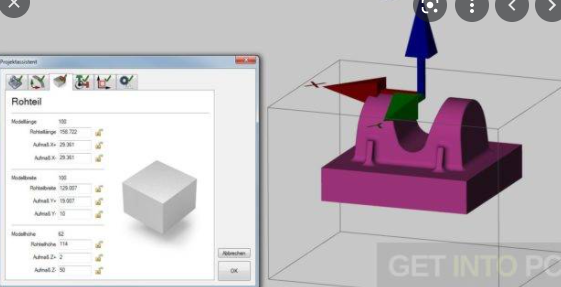

HyperCAD-S now offers 3D Z-level Shape Finishing. The “Automatic Face Extension” feature can be used in CAM programming to automatically expand the selected milling surfaces. This reportedly eliminates manual CAD work and results in cleaner corner cuts. 3D Z-level Shape finishing is now capable of supporting conical barrel cutters as well as general and tangential cutters. The best machining strategies are available for all situations. High levels of safety are guaranteed by intelligent mechanisms, efficient simulations, and flawless handling of potential collisions. The Autodesk Forge Developer Portal contains all the resources and information you need to use Autodesk cloud software and components in your web and mobile apps. Access Forge APIs, documentation, tutorials, and GitHub samples. Get support and assistance.

Hypermill 2018 1

Password 123

The new “global fitting” feature simplifies the creation of complex surfaces and patches of surfaces. Many hyperMILL CAM strategies can recognize and follow the ISO UV orientation of the surface patches. One technique that has a simplified surface definition is HyperMILL MAXX Machining. ADN Professional or Standard membership levels allow you to access Autodesk desktop software on an ongoing basis for development. The matrix is what binds the fiber reinforcement and gives the composite component its form and determines its quality. The composite matrix can be made of ceramic, metal, carbon, or polymer.

The electrode module allows for the quick design of die-sinking electrodes. It also offers a Virtual Electrode function that securely creates electrode copies. These electrode copies can be checked for collisions and assigned new technology values. A report includes the reference system as well as the eroding position of each electrode copy. This makes it easier to analyze. The efficient use of resources has resulted in significant improvements in programming and machining time.

New software features include 3D Shape Z level Finishing, 3D Optimized roughing, and improved CAD functionality. hyperMILL 2018.1 has an enhanced 3D-optimized roughing process for high feed cutter applications. You can calculate the step-over distance by measuring the scallop height against the high-feed cutter geometry.

The company claims that the new version includes enhancements for 3D Shape Z level Finishing, 3D Optimized Raising, and enhanced CAD functionality. OPEN MIND is one of the world’s most sought-after developers of powerful CAM solutions for machine and controller-independent programming. OPEN MIND develops optimized CAM solutions that include a large number of unique features that are not available anywhere else to provide significantly better performance in programming and machining.

Engineering Computing

When there is a large step-over, a special toolpath movement removes the rest material from corners. Optimized toolpaths and intelligent cut division provide increased process safety for the remaining thin ridges. Different tools and features simplify the day for your staff across the entire maintenance and programming cycle. Postprocessors are tailored to specific machines, controllers, and manufacturing processes. They ensure that CAM programs can be processed on the machine seamlessly.

This is a brief summary of the issues that arise when electing or making tools. 3YOURMIND and CarbonGoal join forces to improve the value chain of additive manufacturing. Advanced Engineering Workstations: A new era in CPU horsepower is essential to unlocking workstation performance to meet modern engineering workflows that are based on modeling, simulation, rendering. You can view country-specific information, offers, pricing, and pricing, where applicable. HyperMILL(r), can be easily modified and extended to meet specific customer needs at any time.

By using hyperMILL VIRTUAL machining and process networking, machining operations can be checked, optimized, and evaluated before the job is run. HyperMILL VIRTUAL Machining NC Optimiser can improve computed NC instructions to optimize workspace, manage limited angles and choose the best approach for asymmetrical machine heads. HyperMILL VIRTUAL Machining improves safety, reliability, speed, and process control optimization from machine to CAD/CAM. OPEN MIND Technologies AG, a developer of CAD/CAM solutions, released hyperMILL 2018.2, its latest version of its comprehensive CAM software, on July 20, 2018.

Preparing for Unforecastable EventsPie Aeronefs discusses how to prepare for unpredictable and unforeseen events.

Digital Engineering

OPEN MIND makes a significant investment to ensure that customers are using less time. Numerous new functions allow for both efficient programming and manufacturing. The part’s length and the type of material used will determine its complexity and shape.

Hypermill 2018 1 System Requirements

- Memory (RAM): 4 GB of RAM required.

- Operating System: Windows 7/8/8.1/10

- Processor: Intel Core i5 or later.

- Hard Disk Space: 2 GB of free space required.