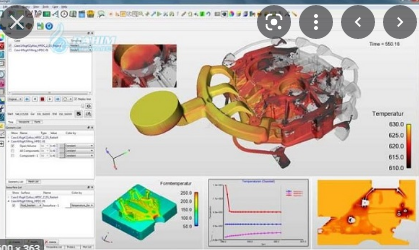

FLLOW3D CAST Advanced 2017 allows metal casters to study the thermal profiles of the molds or dies, as well as the profiles, as well as other properties such as gazing at the inner cores. It allows the models to cut down on design and development costs when they implement new casting techniques. It is equipped with a user-friendly and advancing user interface that will guide you through projects that have been successful, delivering precise predictions of the process of the filling and solidification defects. Its extremely precise flow and solidification results are able to identify critical casting flaws.

Password 123

FLOW 3D CAST Advanced

FLOW-3D CAST aids users and engineers to conduct casting tests using specific and practical tools. FLOW-3D CAST is among the easiest software available in the field of simulation. It is used to cast. It has a simple interface and has a surprisingly powerful 3D capacity to tackle issues. Simulation is a great tool to examine the effects on the temperature at which you first heat your mold as well as the temperature at which it is pouring as well as the pour speed on the process of solidification during fill.

We do not like pop-ups, surveys, or Login prior to downloading because they could irritate users. Everyone is entitled to download Working Software without trouble. Also, I believe the installation should be a single file, as a user, I dislike downloading in fragments. This allows modelers to save on layout costs and the development costs associated with implementing new methods of projecting. Click here to begin the FLOW-3D CAST Advanced 2017 free download. This is a complete offline installation and setup that is standalone to FLOW-3D CAST Advanced 2017.

Another key process parameter is the influence of the mold’s rotation speed in the spread of melting across the length of the mold. The aim of casting pipes is to make sure that the thickness of the pipe is uniform across its length. The cross-sectional view at end of the video illustrates how the melt is distributed across its length. The melt must be evenly dispersed prior to the start of solidification. FOLLOW-3D CAST Advanced 2017 is free to download the latest version through the direct link.

FLOW 3D CAST Advanced Features

It comes with a user-friendly and ever-changing user interface that can guide you through efficient projects, providing accurate predictions of filling and solidification defects. Its ALL-NEW FLOW 3D CAST v5.0 will be a huge leap forward in relation to the simulation of metal casting as well as process modeling. Casters are now able to select the type of process they wish to model and the program will give the proper processes parameters and geometry type and appropriate defaults. Furthermore, FLOW-3D CAST’s powerful simulation engine and the new tools to predict defects offer insight that can speed up the design cycle and cut costs. FLOW-3D CAST is designed specifically to model a variety of casting processes. It also includes the necessary components to offer the complete design solution. The result is a user-friendly interface that, by using an incremental approach, leads users to the FLOW-3D finish, which is a powerful tool that provides accurate fill prediction and freezes violations. To ensure that businesses with different requirements can select the right product for their budget and business processes.

The pipe is cast using Chromium-Molybdenum Steel GS25CrMo4 and measures 1 m in length with a 2.5 millimeters wall thickness. I’ve personally modeled how the casting is filled, prepared for solidification and cooling of many castings, the aim is to increase the cleanliness of the metal and solidity, as well as to manage grains structure, separation, as well as stress-related defects. Our team has experienced a good number of successes making use of FLOW-3D CAST to determine the performance of castings in order to maximize quality and reduce costs through a reduction in scrap, rework, and lead-time. Our aim is to provide free software to those who can’t afford new software. Most highly skilled individuals begin their careers but stop because of financial constraints or other reasons and are unable to purchase the programs to demonstrate their talents and skills.

How to get FLOW 3D CAST Advanced Free

The simulations will provide deep insights into the filling and solidification process of the throw section while checking for various problems. The construction and quality requirements to produce a product in the shortest time possible and with the least amount of expense is achieved by using software simulations. Thus, FLOW-3D CAST provides a broad variety of tools and models to manufacture. The models contain techniques to cast lost foams using Newtonian liquids. If you’d like to make use of the highest quality and accuracy to simulate and design your product this program will be a trustworthy instrument for your needs.

3D CAST Progressed 2017 3D CAST Progression 2017, the most recent version of Stream 3D CAST, is an incredible application that will provide users with a complete stream as warm and warm to an enormous variety from metal-based throwing shapes. It lets modelers reduce the cost of the structure, as well as improve costs are reduced while introducing new throwing patterns. It is equipped with a responsive and intuitive UI that guides your progress through productive ventures and provides precise forecasts for the hardening and filling of surrenders. It’s extremely precise in its stream and results when it comes to cementing. will detect the most basic throw absconds. Overall, Stream 3D CAST Progressed 2017 is an outstanding application that will provide you with a comprehensive stream that is a warm solution to a variety of metal throwing types. In short, the FLOW-3D CAST Advanced 2017 allows metal casters to examine the thermal properties of the mold or die profiles, in addition to other features like gassing their cores.

Overall, The FLOW-3D CAST Advanced 2017 can be described as an outstanding application that provides users with a complete thermal and flows solution for a vast range of metal casting procedures. In conclusion, FLOW-3D CAST Advanced 2017 is a powerful program that provides you with a full process flow and thermal solution for an incredibly broad range of casting processes. Simulations will give deep insights into the filling and the solidification of the casting component, while also monitoring distinct defects such as the porosity of the outer oxide, failed and broken bubbles, and the entrained air. The program is equipped with a user interface that is intuitive and dynamic which will guide you through your job with success, offering accurate predictions of the process’s solidification and satisfying any problems. FOLLOW-3D CAST Advanced 2017. It’s an amazing application that can provide you with full flow and thermal solutions for a broad range of processes for casting metal. The simulations will provide specific insights into the process of filling and solidifying the cast piece while monitoring various defects such as the porosity, surface oxides, collapsed bubbles as well as trapped air. It is also possible to get the FLOW-3D CAST Advanced 2017 free download.

Watch 3D CAST The Progressed Version 2017 is a free download to The most recent version. It allows modelers to reduce the cost of their plans by reducing the cost of development as they introduce new throwing shapes. It’s been equipped with a natural, dynamic UI that guides your success through a variety of tasks, delivering precise forecasts for filling and cementing the absconds.

In addition, it is extremely precise in the result of the flow, and the results of the solidification detect critical casting flaws. In fact, it allows the modelers to save on layouts and developing costs when they implement new casting methods. With an easy and advancing user interface that can guide you through your projects with success, providing precise predictions for filling and solidification defects. FLOW-3D CAST is designed specifically for the purpose of modeling a broad range of casting techniques and comes with all the components needed to create the complete design solution.

This is a computer-generated simulation of an automobile flywheel or bell housing that shows the curves of velocity for an aluminum alloy after a rapid shot from a high-pressure die casting. It’s part of the development phase that allows you to test different options for gating. This video shows a comparison of five gates, which simulate filling from a run below the line of separation to create an 80-millisecond casting fill. The left-hand model in the video shows gates pointing upwards, below the line of separation and the right-hand model depicts gates in the same place and bent at 45 degrees. The simulations provide specific insights into the process of filling and solidifying the cast piece while observing the various imperfections. Allows metal casters to study the mold or die’s thermal profiles in addition to other characteristics like gassing in the die core.

FLOW 3D CAST Advanced System Requirements

- Memory (RAM): 1 GB of RAM required.

- Operating System: Windows XP/Vista/7/8/8.1/10

- Processor: Intel Pentium 4 or later.

- Hard Disk Space: 600 MB of free space required.