For the first time, the configuration settings message will appear. Select the Configurations you require. Interac’s SEA+ software simulates high-frequency and mid-frequency noise and vibration (N&V). SEA+ is a breakthrough technology in the N&V design process based upon the statistical energy analysis method. LMS Virtual. Lab NVH Analysis is an entry-level simulation tool that can predict the noise and vibration behavior under operating loading conditions. LMS Virtual. Lab Advanced Optimization includes additional optimization methods, multi-objective optimization, and robust design techniques. Global Optimization solves constrained optimization problems. Multi-objective Optimization helps you optimize designs that have two or more competing goals.

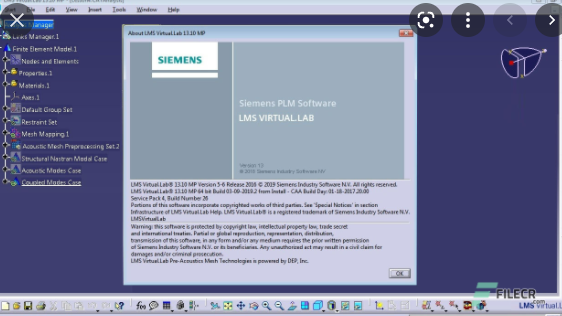

LMS Virtual Lab

Password 123

LMS Virtual. Lab FEA Pre / After is the standard configuration used by simulation engineers to perform linear, nonlinear, and crash finite element analyses using industry-standard solvers. LMS Virtual. Lab simulates the performance of mechanical systems. It includes system dynamics, structural integrity, noise, vibration levels, durability, and motion, as well as control characteristics.

A simulation of energy flows in moving systems (mostly high-speed), such as cars, planes, and jets. This software also has an option to help engineers optimize their systems for their strengths and weaknesses. Identify. This software is also known as the “Siemens Magic Lab”, which is a lab that can perform many engineering tests.

Finite Element Acoustics allows you to create a weak, fully coupled vibroacoustic simulation that will allow you to see how acoustic sources impact the structure. Pre-test analysis is used to determine the best measurement setup for physical structures.

Multibody modeling software allows you to optimize real-world mechanical design behavior and ensure optimal performance before moving to physical prototype testing. LMS Virtual. Lab, a popular product from Siemens, specializes in the simulation, analysis, testing, and maintenance of mechanical systems. There are many parts to this software, each with its own applications. Structure integrity, noise analysis, and system dynamics are just a few of these.

LMS Virtual Lab Features

This software uses the numerical solution to equations in finite element methods and shares many features with FEMAP, NXNastran, and NXNastran. Install the software, and then enter the Variable Value, if required by the server license. Next, copy and paste crack files into the Readme file. Finally, restart Windows and launch the program.

Once you have good test data for physical modeling, structural correlation analysis can be used to quantify the geometrical, as well as dynamic, similarities between the model and the equivalent FE model. LMS Virtual. Lab Finite Element Acoustics is a method of acoustic simulation that helps you to predict and improve sound and noise performance.

Another great feature is the advanced simulation of mechatronics and its widespread application in the automotive and electronics industries. LMS Virtual. Lab component Fatigue allows you to evaluate the fatigue performance of individual components within a single, integrated simulation environment. Combining component loads derived either from multibody simulations or prototype measurements, FE-based stress results, and cyclic fatigue material parameter data, you can accurately predict fatigue hotspots as well as optimize the component design. LMS Virtual.

How to get LMS Virtual Lab Free

Lab Meshing allows for the creation of a complete system for meshing, geometry healing, and performing crash, linear, and nonlinear finite element analyses using industry-standard solvers. The meshing engine uses a combination of an advanced and basic Mesher to automatically and associatively generate a finite element model on wireframes, surfaces, and solid geometries. Interac developed SEA+ software to simulate mid-and high-frequency vibration (N &V). SEA + is a breakthrough technology in the N & V design process based upon the statistical energy analysis method. Pre-test analysis is used to prepare measurements for physical structures by using the modal information from preliminary finite element model models in order to determine the best measurement setup.

You can use the software without restrictions once it is activated. When you see the “Enter license server” prompt, enter the following information in the Name field. Click Next. This step can take some time. Design teams can analyze many design options quickly and efficiently using the LMS Virtual. Lab package. They can then choose the basic design by key functional indicator. The LMS Virtual. The lab package uses the CAA V5 system.

By analyzing the variation of the results, you can create better products. This will allow you to make the design more durable and reliable. Multi-objective Optimization helps you optimize designs that have multiple objectives. You must keep the default path the same as the original location for the software installation. Install the application on your default path. If you get the DADS 9.6 message, choose No. Select the Run Composer Maker option in the last step. When you get the message “Enter your license server” in the next step, enter the following statement in the Name field and click Next.

This package covers all of the necessary procedures and technologies to conduct a thorough design assessment of each of these key issues prior to costly fabrication and testing of a prototype. LMS Virtual. Lab Motion allows you to simulate, model, and analyze the dynamic motion of any mechanical system.

LMS Virtual Lab System Requirements

- Memory (RAM): 4 GB of RAM required.

- Operating System: Windows XP/Vista/7/8/8.1/10.

- Processor: Intel Dual Core processor or later.

- Hard Disk Space: 10 GB of free space required.