The highest standards of cyber-security have been met by the CPU 410. It has been certified and built. Traditional DCS comes with pre-engineered solutions that include templates, standards, and large libraries. DCSs offer unlimited functionality and customization in exchange for repeatability, reliability, and dependability.

Siemens Simatic Pcs 7

Password 123

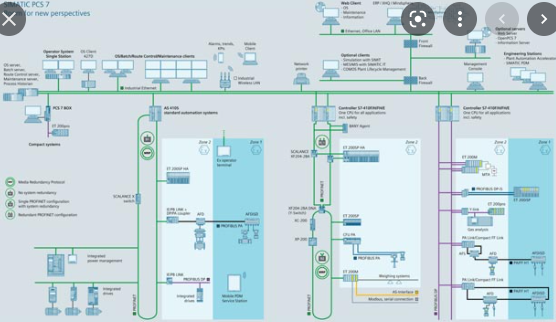

The system will function as a complete solution that includes standard functions. Our trail-blazing system bridges the gap between the present and the future thanks to complete PROFINET support.

The high-level programming languages of the PLC allow you to create custom logic. PLC has a wide range of functions and elements that can be customized and linked together. The ability to create a custom code allows the integration of products and functions into a seamless architecture. Upgrade to SIMATIC PCS 7, and get no-cost support from Siemens process automation specialists. SIMATIC Compact Field Unit, an I/O system SIMATIC Compact Field Unit that allows field devices to be integrated easily, significantly reduces the number and complexity of cables and terminal points, and also minimizes planning and documentation. The Siemens SIMATIC PCS 7, version 9.0, supports the industrial Ethernet standard PROFINET.

Our PCS 7 experts are available to work with you to create a customized DCS upgrade strategy that will help your plant reach new heights of productivity. Intelligent features and expanded functions provide greater efficiency, security, and flexibility.

Systematic Approach to Optimizing Processes

Legacy System Services can also be accessed to offer support, protection, and cost transparency until your upgrade is complete. Plant operation success is dependent on minimal downtime and optimal use of resources and personnel. Siemens developed the Front Adapter Solution to assist Birla Carbon in achieving a simpler, less expensive IO transition that required minimal downtime. SIMATIC Route Control allows project planning, control, monitoring, and diagnosis of material transports on conveyor belts or in pipeline networks.

Software functionalities that are more efficient, safer, and flexible have been enhanced. SIMATIC ET200SP HA is a modular I/O system that offers flexible connections options, a compact design, and high availability through redundant PROFINET connections. Keep up to date with the latest developments and trends in our innovative process control system. There are new opportunities for process automation that can be found in innovative ways of thinking. The Process Automation Innovation Tour brings Siemens’ technology and expertise directly to your doorstep. No travel is required. Jayhawk Fine Chemicals was required to optimize batch production in four plants to ensure consistent high quality for different customers.

APL is a pre-configured, pre-tested set of function blocks, faceplates, and block icons that allow for standardized, simplified, and graphically-based control over all process equipment. SIMATIC PCS7 V9 is the heart of NCERC’s pilot plant. It automates, visualizes, and optimizes core process equipment for each client. The Advanced Process Library is a tool that allows for easy project planning and reliable control.

SIMATIC BATCH now allows you to break down engineering workflows such as recipe design and equipment modeling. SIMATIC PDM V9.1 also allows access to PROFINET components and networks. The choice of a process control system requires more than just advanced technology. We offer world-class technical support, intelligent online assistance, and many other services. Siemens has been working with NCERC for over a decade to increase renewable fuel production using state-of-the-art technology for process control and simulation. SIMATIC PCS 7 uses PROFINET, which is the most widely used industrial Ethernet standard. PROFINET is a critical component of digital transformation in process industries. It provides the foundation for plant-wide, powerful communication in real-time, which is essential in this era of Big Data. Automatic inventory management will ensure that your plant has a consistent approach to making sure all PCS 7 components are up-to-date.

The PROFINETY Switch – Scalance XF204-2BADNA – is easily and flexibly integrated into the relevant automation systems. This allows the connection of S2 devices to high-availability, R1 systems. It can be used in potentially explosive zones 2 environments to reduce downtimes. The highest cybersecurity standards have been met by the CPU 410. Siemens process instrumentation provides a single-source solution for precise and reliable measurements of temperature, flow, pressure, and level. It also allows you to weigh, position, record, and control devices. SIMATIC PCS7 CPU 410 controller series was specifically designed for process automation using SIMATICPCS7 and can be used in demanding environments.

Although the PCS7 cannot be used to replace a PLC it can be used as a tool or method of programming a PLC. The process control system is still controlled by a PLC, but the PCS7 is used for the creation of the control software and interrelations. PCS7 utilizes Win CC to provide a SCADA system for monitoring and acquisition of data in a process environment. The most common types of projects that you could use PCS7 for are Chemical, Energy, Utilities, Food and Beverage, and Pharmaceutical. Standardization of many of the control logic can reduce the time and cost of an engineer learning a project or picking it up. Systems with redundant or duplicate hardware and processes could lead to significant cost savings.

SIMATIC PCS 7, which includes a range of PROFINET-ready and robust hardware innovations, opens the door to plant-wide digitalization. PCS7 V9.1 ensures that your operations are sustainable over the long term by leveraging standardized and reusable process libraries.

Register for our live webinar on Nov 10, 2020, to learn more about Burner Management Systems, heater applications for refineries, and petrochemical plants. Advanced Process Library for SIMATIC PCS 7 reduces the risks, costs, and effort involved in designing and implementing automation projects. SIMATIC PCS 7, SIMATIC Virtualization as a service, SIMATIC Batch, SIMATIC Virtualization as a Server, SIMIT Simulation Platform, and SIMATIC Logon are all examples of Siemens automation technology. SIMATIC Batch, SIMIT Simulation Platform, and a variety of digital process instruments, gas analyzers, and smart electrical devices are some other Siemens solutions. You can reduce operational risks. From new safety-certified I/Os to increased cyber security protection, PCS7 V9.1 will ensure that your plant’s protection levels remain constant. Patti Engineering is a Siemens Solution Partner and can help you assess the available automation technologies to determine the best solution to your business’s needs to run at its peak efficiency. The right solution can make a huge difference in your ROI and bottom line profits.

Siemens Simatic Pcs 7 System Requirements

- MS Windows 10 Pro and Enterprise (64-bit)

- MS Windows 7 Professional and Enterprise (64-bit), with SP1 (and Home version – need edit Setup.ini)

- MS Windows Server 2012 R2 (64-bit) (Standard Edition as work station computer)

- MS Windows Server 2016 (64-bit) (Standard Edition as work station computer)

- MS Windows Server 2008 R2 (64-bit) with SP1 (Standard Edition as work station computer)