Everybody has the right to download working software without any difficulties. Because I dislike downloading multiple files, I believe that setup should be contained in one file. It has a simple, intuitive, and easy-to-use user interface.

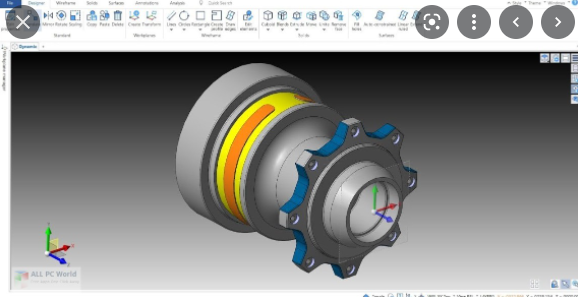

Vero Edgecam 2019

Password 123

Edgecam’s turn functionality was developed with ease of use in mind. Edgecam supports Sandvik Coromant Wiper inserts in turning tools. This allows these productivity-enhancing inserts to work reliably in all aspects of production machining. SoftoTornix offers a wide range of categories that will fit any type of software. We offer more than just software. We also offer support and help. Because it is annoying to visitors, we don’t like popups, surveys, and logins before downloading.

Final step: To purchase the product, install the Download File of Vero Edgecam 2019 Latest Offline and then purchase a serial. Another operating system you can choose is Adobe Prelude CC 2019. Edgecam and Part Modeler can install and run these operating systems in their ‘home’ versions. This is not recommended. We cannot guarantee edgecam and part modeler problems that are specific to these operating systems. We recommend that you update the driver on your graphics card manufacturer’s website if you have problems with it.

Vero Edgecam 2019 Features

This is the ultimate computer-aided design solution for getting your structure up and running through the assembly. It features a very simple, natural-looking, and easy-to-use UI. Direct Displaying allows the client to be free from the limitations of the traditional demonstrating framework. Direct displaying allows clients to drag and pull the geometry to achieve the desired shape, rather than having to change a large number of parameters. Vero Edgecam 2019 is easy to use, thanks to its simple menu and symbol order with touchy online support. The activities can be performed quickly with dynamic pivot, zoom, and skillet tasks. The architect can perform unlimited fix-and-retry activities with clients. Perceptible bookmarks allow the architect to reverse the process as well as advance throughout the structure process.

Direct modeling is a way to create the shape you want, without having to change a lot of parameters. Vero Edgecam 2019 has a simple menu and icon commands, as well as context-sensitive online help. The operation can be performed quickly using dynamic zoom, zoom, and pan. The designer can move forwards and backward through the design process with unlimited undo/redo operations.

It is very easy to use, thanks to its simple menu and icon commands. The context-sensitive online help makes it even easier. Its unique simplicity makes Download Vero Edgecam 2019R1 the best CAM software for all machining, drilling, and turning. Edgecam 2018 R1 now includes ‘Detect Undercut Stock’, which increases the stock detection power by analyzing previously undiscovered areas of stock. This option reduces the time and effort required to machine stock. Edgecam uses your knowledge and experience to drive the CAM process using automation tools that suit different applications. This allows you to keep your competitive edge. Sentinel RMS is a system service that runs on Windows XP (32-bit, 64-bit), Server 2003 (32 bit and 64-bit), Server 2008 (332-bit & 64-bit), Server 2008 (332-bit & 64-bit), Server 2008 R2 (64)-bit), Server 2012 (464-bit), and Windows 7.

How to get Vero Edgecam 2019 Free

Part Modeler includes fully associative drafting capabilities. This tool is a perfect complement to Edgecam Solidmachinist, which provides advanced modeling tools for creating parts and work holding systems like chuck jaws or fixtures. Edgecam can model the major components of a machine tool, allowing for precise cutting simulation and collision detection. Bentley Multiframe CONNECT 21 may also be of interest to you. This standalone installer is a complete offline setup for Vero Edgecam 2019. The unlimited undo/redo operations and user-definable bookmarks allow the designer to move forwards and backward throughout the design process.

This technique is especially important when specialized “Gun Drilling” tools are used. The process requires precise and accurate code output. The Rough Turning Cycle now includes automatic collision detection. Before this enhancement, users had to manually apply for profile extensions in order to avoid collisions. The user will no longer have to manually apply for profile extensions. This will save time in creating the CAM instructions. This function can also be used by strategy managers to create safer toolpaths.

Vero Edgecam 2019 can be used to fill the gap between CAD and CAM. Vero Edgecam 2019 64 Bit is a fully disconnected, independent installation.

SQL Express 2014 has a memory limitation of 1GB and a database limit of 10GB. We recommend that you do not store multiple job images in your database to avoid problems. The command-line option (admin/ExtractJim) allows you to extract job images from the database. This will place the job images in the ToolStore support folder JobImages. If the express version of the database is not available, please ensure that there is enough memory on the server to store the job images.

If they aren’t already installed, the Edgecam installer will install them.

The new “Spring Cuts” command in Profiling Cycle allows the user to make additional cuts as needed to improve accuracy. This feature is especially useful for materials with high elasticity. We recommend that security keys are checked for any updates. This application can bridge the gap between CAD and CAM. Vero Edgecam 2019 is available for free. Here are some of the features you will experience. Vero Edgecam allows you to change all parameters. This includes setting the zero level, shifting the route, and changing the angles.

Vero Edgecam 2019 System Requirements

- Memory (RAM): 4 GB of RAM required.

- Operating System: Windows 7/8/8.1/10

- Processor: 2 GHz Intel Pentium 4 or later.

- Hard Disk Space: 5 GB of free space required.