ONGAA CAM uses both the tool database and the vacuum cup definitions. This means that any new tool must be defined in one location. There are a variety of options for variables, chosen by the programmers. Inform us about bugs, problems, and other unexpected behavior that you’re seeing. Get More Softwares From Getintopc

Password 123

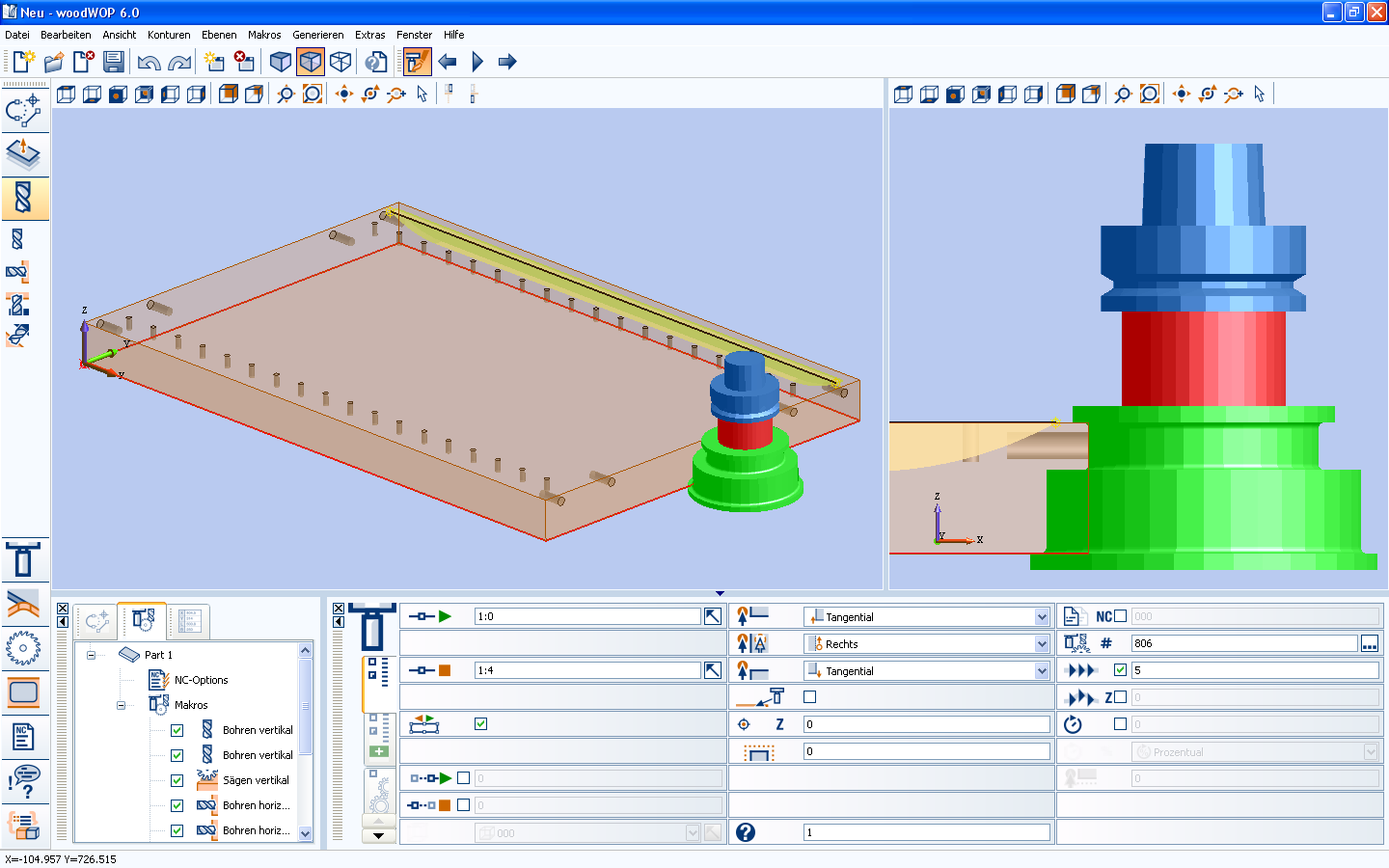

Woodwop

If the block macro’s original modifies all applications that depend on it have to be modified individually and manually. Modifications to the sequence of operation within the component should only be done in the component’s parent and not at the panel level. Components consume more memory and having too many components can make the program load and then process the data slowly. Many merged MPR’s can result in a long array of variables provided that the programmer uses global variables. If the MPR that is merged MPR modifies its design, each application that utilizes the MPR will have to be manually adjusted and individually.

Woodwop Features

The main panel program is able to optimize all the programs merged to make the most efficient use of routers while limiting the number of changes to the tools. I’m aware that the woodwop5 post creates a tool path using the “center” Line option. However, I’m still in need of tools paths that have tools radius compensated.

The individual macros can “X” out by using the Space bar in order to delete them from the NC programmer, however, keep the macro in the list of macros for future usage. The program processes each component prior to going to the next macro. Components may be stored in any machine function: horizontal and vertical boring pockets, saws, and contour routing, for example. If the option to create a new coordinate system isn’t selected the programmers do not have the ability to move the MPR that has been merged MPR and is usually easier to start from scratch. The software I’m running is Fusion 360 with a woodwop 5.0 post-processor that is available to download on this site. This page was translated to your benefit using an automated translation service. It isn’t an official translation and could contain mistakes and incorrect translations.

If we are able to verify your business after successful verification, we’ll include the seal you have been awarded when you post your business’s listings on Maschinensucher. This will let potential buyers know the credibility of your business. This increases buyer confidence and increases the probability of selling machines successfully. Additionally, you can choose of adding a Maschinensucher seal of trust on your letterhead and homepage. Workspace that is useful (X – Z – Y) 3250 x 1250 x 130 (ca.) Work … We’ve created a small test to allow you to examine. We’ve created a basic component, then drawn it in dimensions that allow you to easily make it again and we would like you to determine how long it takes to create a machine-readable part.

Easy to use and provides improved reliability in programming due to its contemporary 3D interface. The program can be further developed with numerous powerful add-ons. A variety of routine processes, including boreholes and saw cuts, as well as pocket trimming, make sure that it’s easy to start the program. Simply save your own process steps to insert with the click of a button using components. Automatically generate milling paths using 3-axis processing interpolating 5 axis processing using a CAM plugin. When working in SOLIDWORKS it is possible to create and apply toolpaths with no need for conversions and DXF files. The files generated by the ONGAA CAM program are Weeke/Homag/Biesse/Hops conforming and don’t require any further manual editing.

The method we’re trying to implement on the machine can be executed with a different computer that isn’t connected to the machine. The two versions appear quite different since the version on the machine has a lot of things that aren’t there.

How to Get Woodwop for Free

If you have modified the model by moving, lengthening, or cutting, the new numbers are recorded to the MPR that was finalized. Model changes are not a problem, and in fact, process programming may begin before the ‘final – ultimate’ model is completed. If you are using the BPP 5 Professional version that has been installed, then layers could be created with specific names. The Week and Homag manuals for machines have sections devoted to the names of these layers and short descriptions of how layers can be utilized. The layers are described in both English as well as German versions, and both can be utilized. From my viewpoint, there is no need for the tool compensation feature of the machine since Fusion is the one that creates the path to the “center” by calculating the diameter of the.

Workpiece dimension – 3050 x 850 x 60mm. Min. workpiece dimensions – 200 x 70 x 12mm. Vector speed – 50m/min (X-Y) & 15m/min . Connection to compressed air 1/8 inch.

User-friendliness is one of the main reasons why ALPHACAM is the standard industry the preferred method of creating CNC routers. The machining and tooling techniques that are unique to this sector are supported by ALPHACAM’s specific Router modules. Horizontal aggregates to machine parts like… In the vertical trimming settings, you can set the Z depth set to match the contour’s Z values, right?

I’m not aware of the specific machine you have, but the task you’re looking for cannot be performed with a 3-axis CNC, but the machine or software that it is running runs as 2.5 an axis CNC. Basically, the drives/controls/software can position Z, but cannot make Z follow a path. This is typically a cost-saving option in the building of machines and is often simply a software lock.

Woodwop System Requirements

- Operating System: Windows 7/8/8.1/10.

- Memory (RAM): 512 MB of RAM required.

- Hard Disk Space: 300 MB of free space required.

- Processor: Intel Dual Core processor or later.