Enhances the way cutting tools cut into the material by employing continuous tangents at high speed instead of sharp, slack motions. Improve the longevity of the cutting tools you use and decrease the stress placed on your machine tools. According to the advice of top tool makers, VoluMill automatically reduces the feedrate when the cutting tool enters the material, and then raises it back to the desired feed rate when it is necessary.

Password 123

VoluMill

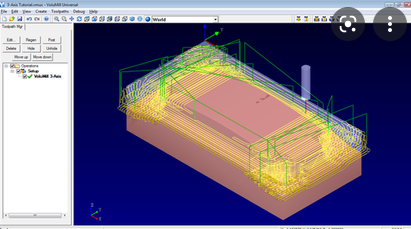

CAMWorks(r) VoluMill(TM) can be described as an alternative ultra-high-performance toolpath engine that is part of CAMWorks for 2.5 Axis and 3 axis roughing processes. VoluMill will automatically determine the order of removal of materials that will reduce the total time of each cycle. Utilize a smaller tool to cut the material that was removed by a bigger tool in an earlier operation. The VoluMill Active Chip Thickness Control lets you precisely control the key elements of the metal cutting dynamic, which gives you better control over the machining process. Toolpaths with constant stepovers typically have shorter paths than other methods. VoluMill maintains a constant stepover wherever possible, resulting in evenly machining loads and uniform chip shape, which results in efficient heat removal.

This GibbsCAM VoluMill Wireframe feature is available with every brand new GibbsCAM milling license as well as GibbsCAM milling licenses are covered through software maintenance. It provides up to 100 percent step-over, with no material that is not cut. Please contribute to proving the validity of the subject by citing credible secondary sources that aren’t tied to the subject matter and offer extensive coverage beyond merely a minor mention. If there is no evidence of notability the article will likely be combined with other articles, moved, or removed. The subject of this article might not be in compliance with Wikipedia’s guidelines on notability for services and products.

VoluMill Features

VoluMill executes all of the intricate calculations needed to find the best cutting technique for any part. It is not necessary to determine individual parts’ features like “faces”, “pockets”, “cores”, “cavities” and so on. VoluMill will choose the most effective approach for the job. The Active chip thickness control allows you to precisely alter the most important elements of metal-cutting mechanics, giving better control over the machining process. It is not necessary to define individual features of the part like “faces”, “pockets”, “cores”, cavities” or any other. No uncut pieces of material will remain behind whatever the dimensions of your stepover. Click the buttons below to print a table of the parameters for the material that is listed.

VoluMill is able to work with any form, closed or open, with many features and is compatible seamlessly with every CAM system. It creates the toolpath on the basis of capabilities that are built into the machine as well as cutting tools. It is able to cut pockets and slots, steps channels, and other forms and handles the most diverse of materials as well as part boundaries and islands.

This innovative feature of VoluMill reduces the amount of shock that your tool experiences and prolongs the life of your cutting tools. Operation Templates make a simple task of capturing and reusing machine-related knowledge. Once established, the ideal configuration of settings and parameters for any machining task that is proven on the machine can be saved and used in other applications in the future. Its unique, patent-pending technology simplifies programming by automatizing the removal of material regardless of the geometry or level of complexity. Workcenter’s user interface features all of Celeritive’s dependable technology-based tools, such as volume(TM), evolution(TM), airframe(TM), and nexion(TM) for 2-, 3- and 5-axis turning and milling. You can dramatically reduce the time it takes to cycle and boost your profit.

VoluMill’s unique method of high-speed material removal lets the programmers determine the optimal speed of removal for each geometry material, machine, as well as cutting device. For soft metals, offers the fastest cycle speed. Selects intelligently slot milling or side milling to boost the removal rate of the material.

How to get VoluMill Free

VoluMill gives these advantages through the full use of the capabilities of modern machining equipment to regulate the speed of removal of material. The toolpath is designed using the features built in the machine tools and cutting tools, regardless of the cut shape. Traditional toolpath strategies, in contrast, originate from the geometry that is being machined by filling the boundary with a zigzag design or offset boundaries until they collapse upon themselves.

You can also view videos of machining tests using these parameters. Thanks to VoluMill’s exclusive techniques for creating transition zones and its sophisticated toolpath design, you are able to be able to cut deeply fast, and securely with the entire flute of the tools. VoluMill can automatically alter the toolpath to prevent collision with an instrument holder or shank. It also has different clearance distances between the shank and holder. Additionally, VoluMill can determine the length of flute required for cutting a particular piece and allow you to choose the right tool to complete the task. This eliminates the need for hand-drawing intricate toolpaths for rough-turning, usually requiring many hours. With VoluTurn programming, you can complete your projects quickly and efficiently at first.

It is compatible with any type of cutting material, including the most difficult metals. To use it, GibbsCAM is an extremely high-performance toolpath that makes use of an uninterrupted, high-speed toolpath for a CNC program that is optimized. These powerful, high-speed, high-material-removal-rate capabilities can help you create the fastest, most efficient toolpath for a wide variety of milling part types in your shop. The procedure automatically considers the most efficient choice for milling pockets. This includes the speed of the tool, which is lowered into the material, as well as the removal rates for the material. The variation in the load of the tool is reduced, which allows the machine to work at more feeds and speeds. The high-performance roughing module that is fully integrated into CAMWorks offers the most efficient milling routes and material removal while also reducing time to machining.

The result is higher effectiveness and efficiency of equipment as well as labor and materials. VoluMill can be the one tool available in the market today that can offer side milling or the combination of slot and side milling. For a variety of materials, it is possible to let VoluMill select the most efficient option of either side milling, or even slot milling as needed will reduce the time it takes to complete a cycle without any additional input by the user. Once the optimal set of parameters and settings for a particular job of machining, as proved by this machine. The algorithm can be saved easily and reused in future applications. Templates for operation significantly cut down on the time required to program and require little other than loading the template you want and setting the appropriate cut Levels. VoluMill enhances the way tools cut through materials, employing continuous tangents with high-speed, continuous speed instead of sharp, slack motions. Field applications show that VoluMill can safely double the machine’s output, increase the lifespan of the tool and help create a more efficient and competitive manufacturing company in the global market.

A powerful, precise tool motion designed for restricted spaces. VoluMill will automatically apply this specific milling process as needed. Cut any combination of stock or part boundaries without difficulty and all edges that are open are fully leveraged for effective milling and to prevent falling into the substrate. It is easy to manage any pocket geometry and effectively cut open designs. Tomak is a workshop that is proud of its cutting-edge manufacturing equipment and highly skilled employees. Scroll down to the end of the page in order to see VoluMill remove material three times more quickly than what you’re currently cutting. HCL offers solutions for the development of products and the manufacturing industry, recognizing the current and future requirements of multinational companies. VoluMill is the quickest, most efficient method of removing bulk material for all milling operations that are not finished.

VoluMill System Requirements

- Memory (RAM): 512 MB of RAM required.

- Operating System: Windows XP/Vista/7/8/8.1/10.

- Processor: Intel Dual Core processor or later.

- Hard Disk Space: 30 MB of free space required.