Applications for CAD-like NX, Solid Edge can export models using this format. It is possible to export 3D data files that are able to be imported in JT format. JT file format ‘.jt’ by using Drag-and-drop. If a machine maker sells a new machine to a manufacturing facility Plant Simulation is a way to show how the client’s production rate will be increased by buying their product. Get More Softwares From Getintopc

Password 123

Tecnomatix Plant Simulation

Choose the folder where you want to download Plant Simulation. Select the zip file, and download it to the directory that you would like to install on your personal computer. Find and highlight issues that may otherwise lead to expenses and require time-consuming corrections in the phase of ramp-up. The ability to import the data of other platforms, like Access or Oracle databases, Excel worksheets, or from SAP. Help us to improve the quality of this article by including references to trustworthy sources.

Tecnomatix Plant Simulation Features

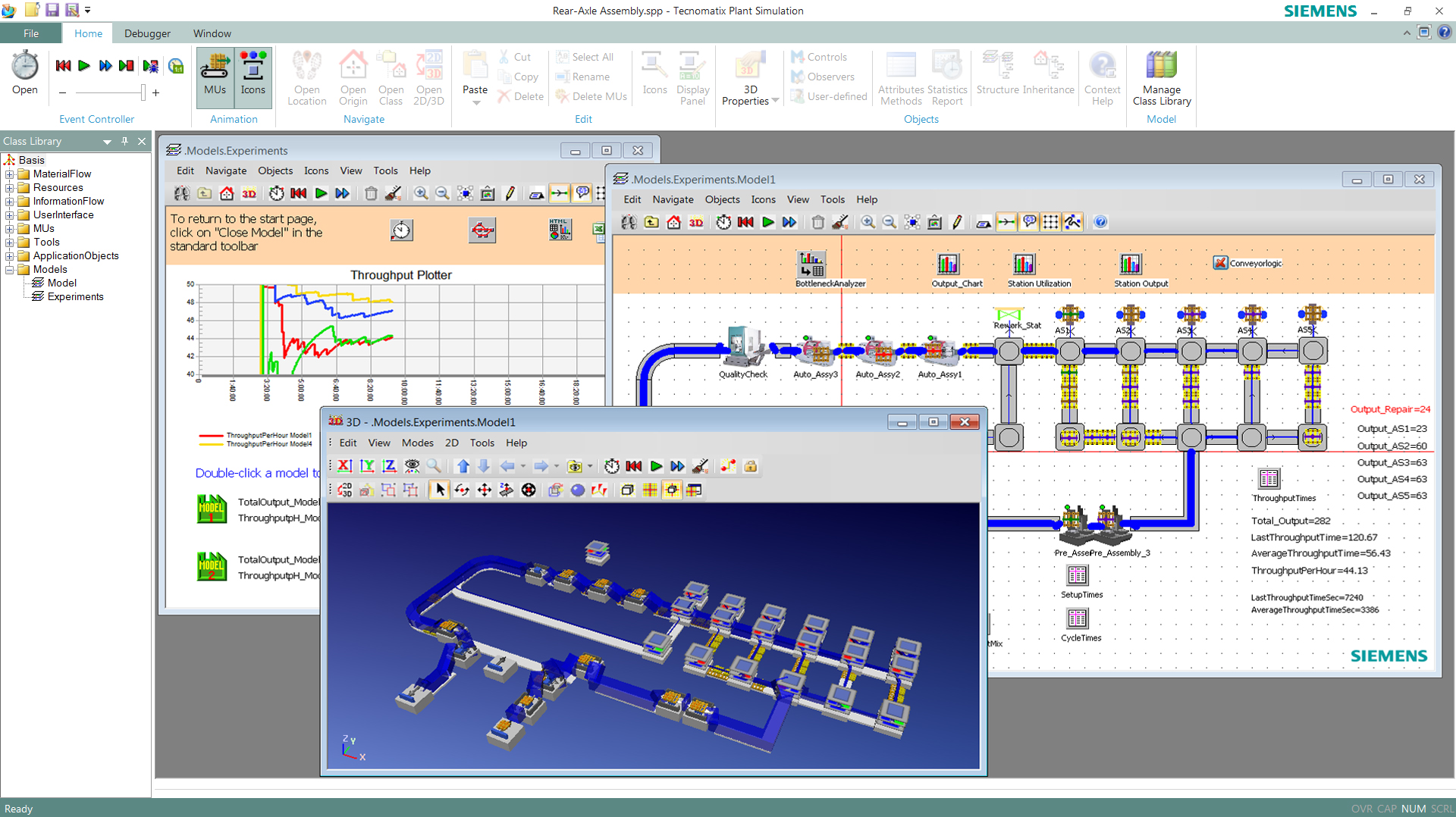

Move to the folder on your computer from the directory where your zip files were downloaded. Then double-click the setup.exe file to begin the installation. These are only some of the ways Siemens Tecnomatix(r) Plant Simulation is an invaluable tool for anyone working in modern production facilities. Through the digital twin, the user is able to simulate the various number of work and shifts in order to determine the optimal use of capital and the return employed. The user simulates by increasing the number of work hours during a shift, and by adding a shift duration. In our example below this is the file Plant_Simulation_15.1_DVD_64bit.zip. The zip file is a complete installation package users can download and then use to start installing Plant Simulation.

In a time of rising costs and production pressures as well as ongoing globalization, logistics is an essential element in the overall success of a business. It is possible to lose money every day due to inefficient scheduling, local rather than global optimization, poor allocation of resources, and low efficiency. The requirement to implement just-in-time or just-in-sequence, implement Kanban as well as plan and construct new production lines, and control global networks of production need objective criteria for making decisions that aid management in evaluating and comparing different strategies. Making adjustments to the process of production in the factory can be extremely long and costly. For instance, If a machine moves, production has to be stopped until the machine is shut down then disassembled, relocated rebuilt, and then debugged at the first startup.

The company has recently begun offering education-related licenses at no cost for Plant Simulation to high school or college students. This means that the software is also suitable for the classroom, sort of speaking. The video is focused on the part of the plant in which kitting — or the process of grouping products into packaging–is carried out. As kits become more complicated the packaging process has decreased in speed, leading to more work to be done. This in turn can affect a company’s profits as well as the plant’s performance indicators. Find the most efficient delivery and production logistics before raw materials begin flowing through the facility. Before that, be sure that your blueprints specify the most efficient use of every square inch of your plant before you invest the first cent on the building.

Simulation of Plant Simulation could be utilized to analyze the effects of expensive modifications before the money is made. The 3D display can be used for sales purposes as well as for internal communication about plans for measures. Additionally, it lets you showcase the entire system in a virtual, immersive, interactive environment to experts in non-simulation.

Material flow simulation has recently gained prominence due to the growing utilization of simulations to assess the environmental sustainability of industrial manufacturing processes. The features that are sustainable in manufacturing can be created and studied prior to the time they are implemented into the investment decision-making process. If you are looking for a simple plant configuration–for instance, a single point of material dispensation, followed by the processing machine and concluding with a shipping station, a flowchart and spreadsheet could suffice. The mapping of the material flow from the dispensary to a variety of workstations, processing machines, assembly points, and packing stations would need a lot more.

How to Get Tecnomatix Plant Simulation for Free

After this huge investment, how will facility managers be certain that the investment was worthwhile? With the help of the Plant Simulation Facility, layouts can be altered and simulated by the software prior to committing resources to make changes to the facilities.

The processes are not able to be described with simple mathematical descriptions and formulas because of numerous interdependencies. Before the advent of computers with high performance, the majority of problems related to simulation of material flow were solved by the use of the theory of queueing and research methods for operations. In the majority of cases, the solutions that resulted from these calculations were difficult to comprehend and were characterized by numerous boundary conditions and restrictions that were difficult to live by in actuality. Siemens Tecnomatix(r) plant Simulation is software by Siemens that can create a “digital duplicate” of a complete facility. Each aspect associated with the plant is represented inside the virtual model, including automated machines as well as manually operated workstations, to conveyors and part buffers and storage.

Transferring layout information that was created by Autocad, Microstation, FactoryCAD, and so on. direct into the model. The Tough Enough rugged workstations that come to that feature professional graphics provide the latest options for engineering on the job. Welcome to Omniverse EnterpriseNVIDIA to offer the AI-integrated, 3D immersive collaborative platform with enterprise subscription plans.

Plant Simulation is a tool to simulate the introduction of a new machine to the existing facility and model the output as well as other production numbers. Library objects include, for instance, digital workers with adjustable productivity settings. They are not animated (so don’t assume that they will move across the factory floor in fluid movements) They are used as representations for calculating distances to workstations, foot traffic, and throughput. Plant Simulation offers a drag-and-drop interface, and library objects that you can apply to. Basic objects like Source Processor, Conveyors, and Workstations are preloaded with default attributes. However, for a more precise representation of your plant, it is possible to create customized entities (for instance the boxing machine, which is accessible most of the time). To accurately create, record, and simulate the interlocking functions of a manufacturing facility in a computer, you might need to create a brand new type of software. Siemens PLM Software’s Plant Simulation, part of Siemens’ Tecnomatix suite, is part of this category.

provides a comprehensive analysis tool to identify bottlenecks, for monitoring the flow of materials, and for detecting resources that are over-dimensioned. PROLIM is a top provider of complete PLM as well as Engineering Solutions to Global Fortune 1000 businesses. We concentrate on technology and business processes and assist our customers in improving their efficiency and profitability. The setup program displays the percentage of installation that was completed.

Tecnomatix Plant Simulation System Requirements

- Operating System: Windows 7/8/8.1/10.

- Memory (RAM): 512 MB of RAM required.

- Hard Disk Space: 2 GB of free space required.

- Processor: Intel Dual Core processor or later.