Technology, a Schlumberger-owned Windows-based software platform that aggregates all wellbore data, is owned by Schlumberger. It was created to address the need for a single platform that can support all wellbore data as well as interpretation integration workflows. This reduces the need for many highly specialized tools. The entire workflow can be integrated into one platform, allowing for the assessment of risk and uncertainty throughout the life cycle of the wellbore. In order to fully appreciate the wellbore imagery data’s value, they must be integrated into a multiwell geological display along with other wellbore data (e.g. tops, core, logs).

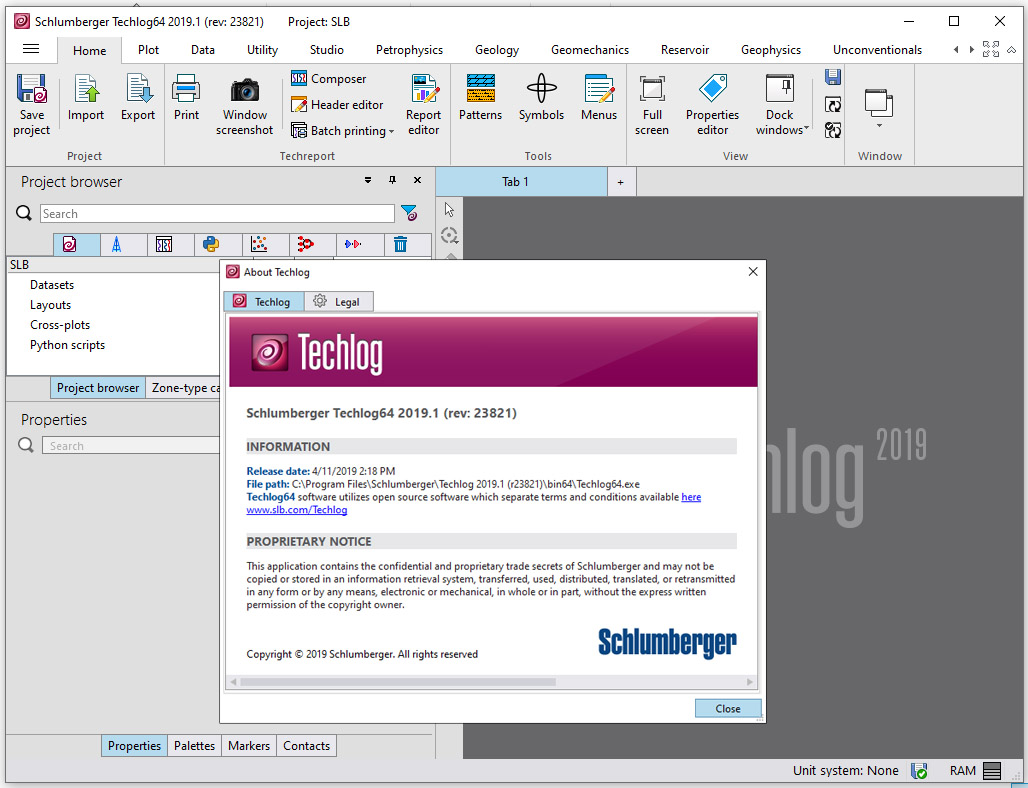

Schlumberger Techlog

Password 123

Techs were acquired by Schlumberger in 2009 and Techlog is now supported and sold. Each new version of Techlog includes new functionality, including geomechanics interpretation and uncertainty.

Technology has a new acoustics module that will enhance the functionality of the application. Technology allows you to interpret all types of wellbore data, including log, core, and images as well as thin sections.

The Techlog platform offers advanced modules for domain specialists, but also provides a solid foundation to generalist users for reviewing and analyzing data. The Techlog Wellbore Imaging module has seen significant development in terms of quality control, processing, interpretation, visualization tools, and other features. For example, the Inclinometry Quality Control module allows you to control quality and repair orientation data. Non-specialists can now easily process images using a wizard that guides them through the entire process. This wizard includes quality control and tool recognition. To enhance your field-development strategy, you can easily upscale and send the results to reservoir modeling.

The secure cloud-based environment allows for new insights. You have instant access to more science via the Techlog platform, and you can instantly gain them. Techlog 2021 has new borehole environmental corrections that will improve processing speed and interpretive efficiency. Techlog 2021 will provide a better user experience and substantial productivity improvements.

A new workflow was developed to improve the petrophysical results from logging and drilling measurements in horizontal wells. The stream is sent directly to the well site and is used for instantaneous analysis and real-time processing. This aids in decision-making during operations. Next, a Schlumberger Company, provides software, technical training, and career development solutions to E&P professionals and organizations worldwide. Technology, the largest oil and gas measurement acquisition firm in the world, uses the Techlog platform extensively to prepare answers for you. These answers are delivered quicker, with more context information and incomplete transparency by working with the same software. Detail 3D interpretations increase the value of the complex data from modern wells.

Technology provides efficient links between the wellbore scale and geological models, geomechanics, and reservoir engineering within the Petrel E&P platform. These developments, along with other visualization enhancements and processing enhancements enhance the sharing and interpretation of image data across all team members. This complements the existing multiwell processing, data integration, and data integration offered by the Techlog platform. Analyses can be performed in real-time to increase efficiency and decrease turnaround times from drilling to analysis. You can either use the Techlog menu selection to run canned models or create your own evaluation scripts to optimize interpretation for special situations. Technology’s best-in-class science allows for the analysis of all wellbore data at their acquisition scale. This allows those data to be up-scaled with confidence. High-resolution data can be used by petrophysicists to determine fluid flow within and around the wellbore.

To generate quick-look interpretations, you can create your own petrophysical workflow. This is based on local knowledge and industry standards for porosity and saturation. The data from wellbores is complex and varied. It also represents a large investment. It is important to make the most of that investment, regardless of whether you are drilling a deepwater exploration well for the first time or continuing to drill in a shale play. Technology allows you to bring together all your wellbore data in one intuitive application that can be used for analyses.

DELFI’s cognitive E&P environment unites operations and planning. Bringing together advances in technical disciplines such as artificial intelligence, data analytics, and automation–underpinned by decades of unrivaled domain knowledge–the result is an E&P experience like no other.

Log measurements that are azimuthally sensitive no longer need to be “make do” using 2D displays. Technology’s platform offers new visualization options for the near-wellbore model. The 3D view allows you to visualize dip picking. This improves geological interpretations of wellbore images. It also helps you understand fracture distributions and how they relate to the reservoir structure. The unique ability to do fracture characterization at the field level is possible with workflows that include fracture aperture computations, automatic recognition and orientation sets for fractures, and fracture statistics. After reservoir mineralogy is fully understood and confirmed with core data, log responses using neural networks can be used to extract facies from geological and reservoir attributes.

The single-well model can then be used to create a multiwell interpretive that will provide the input for a simulation model that evaluates dynamic behavior in the reservoir. To maximize the return on your investment in Schlumberger software, we combine integration, application, and discipline. Through a simple drag-and-drop interface, all common data formats, from various vendors and data vintages, can be easily imported into the Techlog platform. To quickly create a log view, you can validate and correct environmental and signal-noise data. A workflow-oriented platform allows you to log and interpret conventional core data. Real-time interpretation is possible with most AWI-like Techlog modules (e.g. the Quanti or Python modules). Quanta Geo photorealistic reservoir geology service redefines oil-base mud imaging to produce highly detailed core-like micro resistivity photos that visually represent formation geology.

These attributes enable you to understand the permeability behavior of reservoirs. Logs can be used to model permeability, weighing them with core data, and comparing them against previous results. Access to real-time data processing, drilling data models, and other tools can enhance analysis and interpretation.

Schlumberger Techlog System Requirements

- OS: Windows 7/8/8.1/10

- Memory (RAM): 1 GB of RAM required.

- Hard Disk Space: 600 MB of free space required.

- Processor: Intel Pentium 4 or later.