This is due in large part to customers opting for perpetual licenses of CAM software rather than a subscription. Simulating Vehicle Design in a Risk-Free Space. As vehicle design becomes more complex, simulation allows design teams to safely and securely simulate the designs before they are made road-ready. In keeping with the 10-year anniversary of NCG CAM v17, it will be available at the end of this summer. It will be the first version to feature the modern ribbon-based user interface. Micro-Precision 3D Printers: The Case for Micro-Precision 3DPrinting. Micro-precision 3D printers can be used to create small and highly detailed components and products. SolidCAD Launches Make Productivity for Autodesk PowerMillMAKE Productionivity for PowerMill can be used to increase CAM programming productivity.

Ncg Cam

Password 123

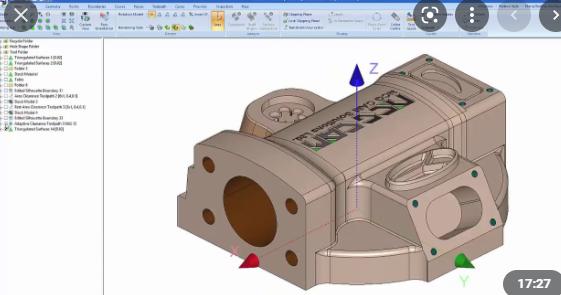

NCG CAM, a standalone CAM system, offers an easy-to-use HSM CAM solution. It integrates with existing CAD systems such as SmartForm Design(TM), Think3 (TM), Ansys[tm] SpaceClaim[tm], CREO[tm], Pro/ENGINEER[tm] and SolidWorks[tm]. It can be used on all forms and creates a smooth, optimized cutter motion for HSM. This helps to prolong tool life, minimize wear, and produce parts with an exceptional surface finish.

This news has resulted in NCG CAM Solutions Ltd offering 41% off all Multi-Seat Orders for NCG CAM Perpetual Licenses up to December 2019. NCG CAM Solutions’ CAM Software, now known as NCG CAM, is designed for advanced 3D milling. Hexagon brings product-as-a service model to Metrology. This new offering provides access to metrology equipment maintenance and certifications without the need to make large capital investments. The “House of Dust” 3D Printing Technology by WASP

Making the Case for Micro-Precision 3D PrintingMicro-precision 3D printing can help manufacturers affordably create very small, highly detailed products and components. Digital Engineering receives news from DE’s editors. Get engineering news from over 90,000. Join them.

NCG CAM Standalone Software makes it easy to machine complex parts. NCG CAM can be used to machine complex parts, such as prototypes, molds, and prototypes at high speed.

Digital Engineering

NCG CAM is very easy to use. It takes just one day to machine a job. This tool is ideal for high-speed machining molds, prototypes, and precision surface machining. The company says it is compatible with all forms. It creates an optimized, smooth cutter movement ideal for 3D high-speed machining. This will increase tool life, minimize wear on machine tools, and produce parts that have a high-quality surface finish. The NCG CAM standalone CAM is ideal for high-speed machining molds, prototypes, and precision surface machining.

Soon, your browser will redirect you to the requested content. Applitools eyes scan the screens of your apps and analyze them as if they were human eyes and brains.

Applitools Eyes will detect all differences in material, but also recognize and ignore those that aren’t.

The VERICUT model and definition of each machine tool’s kinematics, as well as the CNC control, are both precise. This ensures that the checks reflect the exact behavior of the CNC machines. The ability to verify the code used by the machine’s control system and machine can reduce the need for costly programming errors and eliminate the possibility of costly collisions. NCG CAM Solutions celebrated 10 years of trading at the end of June 2019. According to the company, sales figures for the year have seen a jump with 41% growth compared to last year.

It can be used for high-speed machining prototypes, molds, and precision surface milling. The NCG-to-VERICUT Interface seamlessly integrates both programs to allow you to create the most precise and efficient NC programs. This interface makes it easier to optimize and verify NC programs, and simulate CNC machines, and also makes it more efficient. The tools and NC programs created in NCG CAM can be easily transferred to VERICUT by using a command after processing. The company’s CAM software, now known as NCG CAM, was originally launched 22 years ago. It is designed for advanced 3D milling. NCG CAM HSM is a standalone CAM system that can be integrated with existing CAD or CAM systems.

Ncg Cam System Requirements

- Memory (RAM): 1 GB of RAM required.

- Operating System: Windows 7/8/8.1/10

- Processor: Intel Dual Core processor or later.

- Hard Disk Space: 500 MB of free space required.