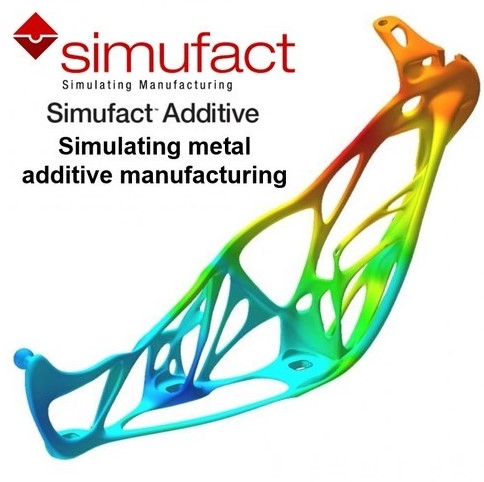

Simufact Additive, along with other MSC Software solutions, covers a wide range of digital additive process chains. Simufact Additive faces a significant challenge in sintering. This cannot be modeled using simple shrinkage models. We consider the following important phenomena in the sintering process: thermal strain, shrinkage, and friction. The thermodynamics of sintering, workpiece heating, and heat transfer into dies and the environment, temperature rise due to forming energy, friction, heat, etc. This feature allows for a fast and efficient calibration algorithm that dramatically reduces the time it takes to calibrate while increasing stability, robustness, and reliability.

[wbcr_php_snippet]: PHP snippets error (not passed the snippet ID)_Getintopc.today_MSC.Simufact.Additive.1.0.Win64.rar[wbcr_php_snippet]: PHP snippets error (not passed the snippet ID)Msc Simufact Additive

Password 123

Simufact welding software is an advanced simulation suite that simulates welding processes. Simufact welding predicts weld stresses, distortions, as well as the evolution of material properties, and helps to determine strategies for minimizing these risks. Simufact has formed partnerships with 3D printer suppliers to create an integrated approach that combines AM simulation software and vendor-specific 3D Printers/ resp. Simufact’s goal is to provide the best configuration possible using fully-coupled simulation-based optimizing. Simufact Additive, a standalone product, already covers key parts of additive manufacturing’s digital process chain. Our customers can combine software solutions from MSC Software with other software and hardware solutions, such as those from Hexagon Manufacturing Intelligence or third-party suppliers to create complete solutions and individual process chains.

Msc Simufact Additive Feauters

Simufact additive is the first multi-physics dedicated Metal Binder Jetting simulation solution. It focuses on distortion due to the post-build process and its automated distortion compensator. Simufact Additive provides a robust and scalable simulation environment that allows for the optimization of Metal Additive Manufacturing processes. The company was founded in 2013 and serves a variety of industries including aerospace, medical, space, oil, and gas, die mold, and medical. Our services include rapid prototyping and conformal cooling as well as DFAM consulting. These services are crucial for partners in terms of quality and sustainability.

Simulating Reality magazine by MSC introduces new solutions for additive manufacturing technologies in plastics and metals. This magazine provides insight and examples into the future AM simulation – using MSC’s extreme and Simufact. Simufact Additive uses MSC Software’s proven MARC solver technology. Marc is the most popular solution for nonlinear numerical simulations. It covers a wide variety of physical effects. Marc was specifically designed for additive manufacturing. Simufact Forming’s standard user interface makes it easy to use the software and allows developers of processes and dies to simplify their work.Learn how Simufact Additives can be used to optimize metal 3D printing/rapid prototyping.

To optimize 3-D printing, process control variables can be chosen to reduce waste and time. SIMUFACT additive, a powerful and scalable simulation environment, allows for the first-time optimization and prediction of metal additive manufacturing processes. It can also predict the final distortions and residual stresses of metal 3D-printed parts. Simufact is a leader in simulation solutions for all metal manufacturing process chains. These include metal forming and mechanical and thermal joining operations, as well as additive manufacturing processes.

Simufact’s products can optimize these manufacturing processes by reducing cost and time to market while still delivering accurate results.

The process-related iconsSimufact Additive is equipped with an intuitive, user-friendly GUI that ensures an exceptional user experience. Flexible GUI design allows for machine- and application-specific dialogs that are aligned with real process flow. For the rapid and automatic discretization of large and complex structures, any shape, a meshing capability has been added. This GUI was designed to handle meshes with more than one million elements. Hexagon’s AM solution is open-source and can integrate third-party solutions.

How to Get Msc Simufact Additive for Free

MSC Software, a leader in simulation software and related services that enable product manufacturers to improve their engineering methods, today announced that it had signed an agreement with Objectify Technologies Pvt. Ltd. will use MSC’s Simufact Additive for Additive Manufacturing Simulation and the MSC One product suite. Simufact Additive, a leading Additive Manufacturing product from MSC Software, provides simulations of manufacturing processes for the metalworking sector. Simufact Additive 2021 has a new type of machining, which expands its application range. The new version includes many enhancements that increase the usability, efficiency, and productivity of your additive manufacturing process simulation. Simufact additive is the first dedicated multi-physics simulation tool for metal binder jetting and sintering. It focuses on distortion caused by the post-build sintering process, as well as its automated distortion compensation.

Flexible GUI concepts allow machine- and app-specific dialogs to be oriented to real work processes. Simufact Additive 2021 has a significant speed improvement in support generation and slicing. It is now up to 10x faster than the previous version. Finely meshed geometries, filigree support elements, and a faster speed pay off. Our latest Simufact Additive 2021 version offers a faster and more robust Metal Binder Jetting simulation. Copyright(c), 2021 simulcast Engineering gmbh. This is part of Hexagon’s Manufacturing Intelligence division. Verify the quality and safety of welding seams. Calculate nugget sizes, brittle metallic phases, hardness, effects of preheating, and quality of welding seams. “I am confident that Objectivity’s Additive Manufacturing business will grow, and I am thrilled they chose us to be their partner.”

All standard-forming processes can easily be simulated and evaluated with just a few clicks. In the MSC magazine Engineering Reality, the article describes how Simufact, MSC, and Hexagon technologies were integrated for two demonstration projects in additive manufacturing.

Renishaw’s QuantAM software build preparation will be paired with Simufact Process simulation software. This will allow data exchange using QuantAM’s API. Next, Renishaw’s QuantAM software will automatically create a simulation using the build information. In return, Renishaw’s QuantAM software will display the simulation results.

A special compensation algorithm specifically designed for MBJ processes allows for increased stability during the optimization of distortion compensation. The specially developed solver for MBJ processes simulation allows for a speedup of up to 17x.

Msc Simufact Additive System Requirements

- Operating System: Windows 7/8/8.1/10

- Memory (RAM): 1 GB of RAM required.

- Hard Disk Space: 1 GB of free space required.

- Processor: Intel Dual Core processor or later.