To determine the effect of mold inserts on melting rate, cooling rate, or part warpage, run an insert overmolding simulation. To determine the input variables that influence the quality, such as mold temperature or injection time, use DOE analysis. This software can provide geometry support for both thin-walled and thick-walled applications.

Autodesk Moldflow Advisor 2019

Password 123

CATIA V5, PTC Creo, and Alias can be used to import and mesh solid geometry. Dual Domain(TM), a technology that simulates solid models of thin-walled components, allows you to create them. It is easier to simulate design iterations by working directly from solid 3D solidCAD models. Before you choose this product, please select another product. Contact us for more information and to schedule a demonstration. We may need to give you country-specific terms depending on where your home is. A unique code will be sent directly to your phone in order to verify your account.

For 30 days, you can have full access to all features and capabilities at no cost.

Autodesk Moldflow Advisor also allows you to perform 3D analysis on parts with different thicknesses and layouts of the cavities. It also includes a balance slider. Autodesk Moldflow Advisor software allows you to simulate the molding process.

Moldflow can be used to simulate and optimize plastics flow behavior. DME uses Moldflow to validate and verify mold temperature uniformity. This helps solve customer cycle time problems and ensures conformal cooling. To optimize cooling, filling, and warpage, simulate thermoset material flowing on part inserts. Analyze and assess the effectiveness of multiple injection molding barrels for filling injection-molded parts. Simulate the effects on molding over part inserts and a two-shot over-molding process to optimize filling, cooling, and warpage. To reduce cycle time and avoid short shots, predict the filling and curing times when molding around a fiber matrix perform. Find the ideal gate location, determine conditions that cause premature curing, improve molding times with LSR materials, and identify these conditions.

Features Of Autodesk Moldflow Adviser 2019

Educational licenses including new, upgrades and migrations, and education-to-commercial transfers do not qualify. This promotion does not apply to product licenses purchased through the Autodesk Employee purchase program. This offer cannot be combined with any discounts or conditions offered by the Major Account program. Use the standalone version of CAD software or the plug-in to identify design concerns for manufacturing during CAD creation.

Simulating Moldflow with Ultimate software reduces the need to make expensive prototypes, prevents manufacturing defects, and allows you to bring new products to market quicker. Moldflow(r), simulation software allows you to troubleshoot plastic injection and compression mold problems. You can address manufacturing problems with advanced tools and a simplified interface, including part warpage, cooling channel efficiency, and cycle time reduction.

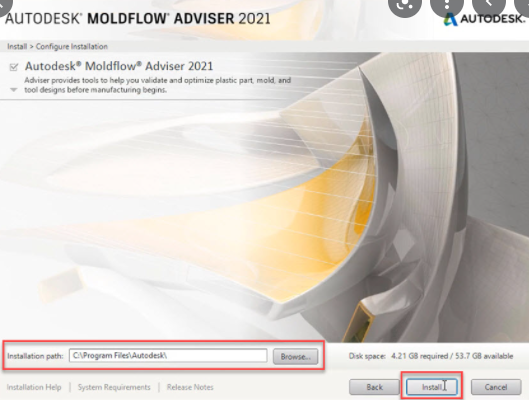

Point out areas of the design that are not in compliance with plastic product design guidelines. Turn off any active programs, including antivirus software, before you start. You may not find this software compatible with your system. However, you can download it to install it on another machine. You can easily share your Moldflow analysis results using template reports in HTML and Microsoft Word. You can inject 2 materials into one cavity and calculate their relative distribution and locations.

Simulate flip-chip embedding to predict material flow between substrate and chip. Calculate the impact of in-mold labels upon the cooling and flow behavior of the mold. To achieve smooth surfaces and rapid freezing, set up variable mold surface temperatures profiles. This will reduce cycle times. Simulate the effects of conformal cooling channels upon temperature distribution during the molding cycle. You can identify potential defects like sink marks, air traps, and weld lines. Then, rework the designs to avoid them. To minimize warpage and surface defects, optimize packing profiles.

All files and programs have been manually installed before uploading. The program works perfectly without any problems. This standalone offline installer setup of Autodesk Moldflow advisor 2019 free download for Windows-supported versions. Choose from over 100 mold materials that have the right thermal properties to perform cooling analysis.

Next, check the Use Services and Start Server At Power Up checkboxes and then click Save Service. Moldflow Design software will be available until Autodesk Simulation DFM 2015. You can join millions of others by entering your email address to receive email notifications about new posts. You can see a summary of the number of people using each product, version, and overall frequency of usage. The US manufacturer used a combination PowerMill, Moldflow, and PowerShape to design and produce high-quality injection molds. Multiple simulations can be run simultaneously with remote server and cloud solving. You can mesh and solve Insight jobs using remote, local, or secured cloud servers.

Quickly identify the recommended processing conditions for packing and filling analyses. Material choice, cycle time, and post-molding operations are all factors that can be used to estimate product costs. To analyze parts or mold inserts, complicated cooling systems, cold and warm runner designs, heaters and induction coils, import assembly files. Directional feedback for standard part, mold, and process designs. You can help predict and reduce optical performance problems such as blurring or double-images.

Autodesk Moldflow Advisor 2019 System Requirements

- CPU : 2GHz CPU speed or faster

- Number of Cores : Minimum Quad-core recommended

- RAM : 8GB RAM or higher

- Hard Disk Space : (12GB or higher free disk space (2GB MB free disk space for installation

- Graphic : 512MB DRAM or higher OpenGL-capable graphics card