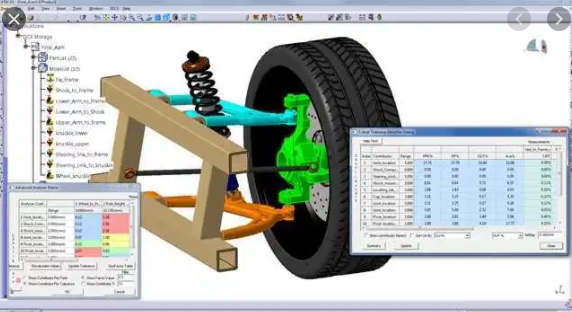

Users can now define different assembly methods, tolerances, GD&T, and measurements within the same model. They can also swap between variants with the push a button. It is now possible to create different scenarios and model parts or processes from different suppliers. It is easy to switch between variants, run analyses, and compare outputs with the cloud-based distributed multi-core and cloud-based processing. Our comprehensive Variation Analysis Courses are focused on Dimensional Control Systems software solutions and cover data management and tolerance analysis. These courses are designed to help users understand the functions and techniques of each software solution.. Get More Softwares From Getintopc

3dcs Variation Analyst

Password 123

You can accurately model the assembly to see how the process and tolerances affect the product’s variation. This creates a virtual prototype that can be used to decide on design changes or tooling, and reduce non-conformance which leads to scrap and rework.

Engineers can simulate products in a digital environment to allow them to account for variations in key areas. This allows them to reduce rework, nonconformance, and scrap at a final assembly in the design phase when the costs of making changes are the lowest. 3DCS is fully integrated into your CAD platform and allows engineers to gain real insight into the designs.

3dcs Variation Analyst Features

3DCS Mechanical Modeler comes with built-in tools such as the Degree of Freedom counter. This allows users to tackle new types of models and applications. This allows users to create products in multiple CAD systems from one platform.

3DCS Geofactor can be used to assess the geometry of a part and the impact of the assembly sequence, positioning strategy, and assembly process on quality during the design phase. This will improve the design’s robustness and process. 3DCS FEA compliant modeler makes it easier to quickly model deformable parts. Engineers can simulate dimensional changes in the assembly more accurately with the 3DCS FEA Compliant Modeller. You can use sheet metal, plastic, glass, or composite materials to deform the parts.

GENESIS Structural Optimization and Analysis Software is a comprehensive analysis and design optimization program, developed by top structural optimization experts. Participants will learn how to import CAD and data files, create QDM templates, and populate quality templates for automated and custom reports. DCS has been supporting quality in various industries, including aerospace, automotive, medical device, and electronics, for more than 20 years. Companies like Airbus, Embraer, BMW, and General Motors use DCS solutions daily. 3DCS Mechanical Modeler, an add-on module to 3DCS software solutions is available in all versions. It includes a new toolbar that contains Joints and Constraints and Mechanical Moves, Deviation In Motion, and the Degree of Freedom counter. Integration with the FTA module within SOLIDWORKS allows for seamless transfer of GD&T data into 3DCS, saving time and allowing you to annotate once again.

The component can move in a specific range of motion in the direction of unconstrained degrees of freedom. It can also calculate simulation results at multiple positions. Creo integrates 3DCS with Creo, allowing users to access embedded geometric dimensioning (GD&T), and other tools. Every class is unique because every product and assembly is different. Each class is customized to meet the needs of each participant. You can either use a DCS-certified training model or bring your own. Expert help is available for applying the Addon module immediately.

How to get 3dcs Variation Analyst Free

The 3 DCS analysis model can be used to visually inspect the assembly process and determine the deviation. The GD&T interface was redesigned to make it easier to create GD&T from CAD models and to validate existing GD&T. All versions of the software can use extracted PMI from CAD models, but this new interface makes it easy to access that data when it is not available. DCS clients around the world can now use the software’s ability to extract PMI from CAD models. 3DCS FEA compliant modeler is an add-on module for the 3DCS software solutions. It uses FEA methods and FEA methods in order to accurately simulate variation within compliant parts and assemblies within 3D Variation Analysis. The integration designer allows you to seamlessly transfer your model from SOLIDWORKS to 3DCS. You can then analyze it for variations without losing any data.

This allows you to get the best possible results and make informed decisions about your manufacturing process. Additionally, less important specifications can be reduced, increasing tolerances, and allowing for the use of more expensive manufacturing processes. Engineers can create 3-dimensional tolerance stack-ups that help them determine where to concentrate their efforts. They also have the ability to create what-if analyses, which allows them to identify solutions that incorporate both process and tolerances in order to reduce costs and improve quality. 3DCS Variation Analyzer Multi-CAD is an independent tolerance analysis software that simulates product assembly. It also allows for part tolerance 3D stackups using Monte Carlo Analysis. 3DCS Variation Analyzer Multi-CAD is an independent tolerance analysis software that simulates product assembly. This feature is a popular one that allows users to create different builds of the same model. This allows for better version control and eliminates the need to create multiple copies of the same model.

These studies can help you to control both the perceived quality of your product and your build quality. The source of variance is often in the assembly process. This solution doesn’t require changing tolerances. Engineers can improve quality without needing to adjust tolerances. Tolerance and process changes can also be simulated in the model to determine the optimal conditions for achieving the highest quality and lowest cost. All of these studies can help improve your Perceived Quality and build quality. 3DCS Variation Analyst is the best tool for tolerating variations. It allows users to analyze the relationships between parts and accounts for many sources.

It is a library of connections and constraints that can be used to build assembly models. It can be rigid or flexible and move within a specified range. The multi-step deviation simulation result can also be calculated during the motion. Engineers can simulate products in a digital environment to reduce rework, nonconformance, and scrap during final assembly when it is most cost-effective. This class often incorporates a customer’s product or model to demonstrate modeling techniques specific to the industry, function, and assembly. It is designed to assist engineers in creating larger models and accurately modeling manufacturing processes. 3DCS MultiCAD can instantly tolerate your parts using embedded GD&T and PMI from your CAD. To validate your tolerances, simulate the build and make adjustments to improve cost, quality, or variation control.

3DCS MultiCAD allows companies to save on licensing costs while still being CAD neutral. This is especially useful for Engineering Services. It allows companies to choose from different CAD systems depending on their customers’ platforms.

To determine the visual impact on variation stack-ups, create life-like images showing your product in worst-case scenarios. These studies can be used to establish maximum and minimal tolerances in design. Engineers can also use these studies to communicate with them. After engineers have established the manufacturing tolerances, you can recreate the studies to see the final product with the worst-case tolerance stack-ups.

System Requirements for 3dcs Variation Analyst

- RAM: 8 GB

- Operating System: Windows 7/8/8.1/10

- Processor: Intel Corei7 or Xeon Processor

- Hard Disk: 4 GB

- Office 2016/365

- Browser: Microsoft Edge, IE 11, Google Chrome, Mozilla Firefox